The MS-2000 XYZ stage has been specifically designed to provide a high resolution, and highly repeatable, means of controlling the X, Y, and Z position of the microscope stage. All axes derive their precise control through the use of closed-loop DC servomotors employing high-resolution rotary encoders for positioning feedback. Optional linear encoders improve repeatability to less than 300 nm (typical) compared to the standard rotary encoder's 700 nm (typical) repeatability rating.

By using closed-loop control of the stage position, there is no chance that the stage will become lost, as can occur with open loop micro-stepped stages after a number of moves and direction changes. The MS-2000 XY stage utilizes crossed-roller slides, a high-precision lead screw, and zero-backlash miniature geared DC servomotors for smooth and accurate motion. The Z-axis drive also uses line of closed-loop motor drives, each custom fitted to the microscope. The microprocessor-controlled MS-2000 control unit provides for RS-232 and USB communication with a host computer.

Upright Stages

The smaller MS-2000 shown in the above photos is a compact stage that fits very well on smaller upright microscopes such as Leica's DML-series, Nikon's Optiphot, E400, and E600, Olympus' BH-2, BX50, and BX51, and Zeiss' Universal and Axiolab. The smaller MS-2000 also works very well as stand-alone stage for XY positioning applications.

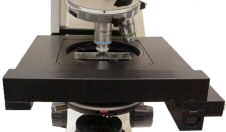

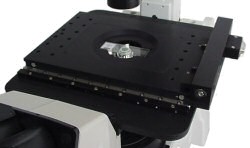

Inverted Stages

The MS-2000 stages for inverted microscopes,are designed specifically for each microscope model. This allows us to address clearance issues such as the large objective turrets of inverted microscopes. As shown in the photos above, the MS-2000 inverted stage has a slim profile and accommodates a wide range of slide inserts like the universal slide insert, shown here, which is suitable for a variety of slides and dishes.

Features

- Closed-loop DC servo control of the X, Y, and Z axes for precise positioning and highly repeatable focusing

- Wide dynamic speed range with XY joystick control

- Z-axis clutch for easy switching between manual & motor-driven focus control

- Backlit LCD display shows X, Y, and Z coordinates

- "Zero" and "Home" button for simple stand-alone operations

- Compact ergonomic tabletop control unit size is 6"D x 9"W x 3"H

- Microprocessor control with RS-232 serial and USB communications

- Proven operation with many popular software packages

- Suitable for stand-alone, OEM, and specialty applications

Specifications for Standard Configuration (with 6.35 mm pitch Lead Screws)

| XY axis range of travel |

Upright: 100 mm x 100 mm |

| Inverted: 114 mm x 90 mm |

| XY axis resolution (encoder step) |

22 nm |

| XY axis RMS repeatability |

< 700 nm (typical) |

| XY axis maximum velocity |

7 mm/sec |

| Z axis resolution (encoder step) |

50 nm |

| Z axis repeatability |

± 100 nm (typical) |

| Z axis maximum velocity |

0.6 mm/sec |

MS-2000 Options

- X, Y, & Z axis Linear Encoders † for high-accuracy positioning and focus control

- Larger stage top-plate for attachment of micromanipulators, etc.

- Stage Wings † on inverteds for even more room for attachments

- Stage Inserts to hold a variety of slides, dishes, sealed glass chambers, multiwell microplates, perfusers, heaters, and many other special items

- Auto Focus for stages

- CRIFF Continuous Reflective-Interface Feedback Focus System for high level long-term focus stability on high-power XYZ microscopy systems

- Other lead screw pitches are available, as shown below

Lead Screw Options

| Lead Screw Pitch Options |

Rotary Encoder Resolution |

Maximum Speed |

| 25.40 mm (Ultra-coarse) |

88 nm |

28 mm/sec |

| 12.70 mm (Super-coarse) |

44 nm |

14 mm/sec |

| 6.35 mm (Standard) |

22 nm |

7 mm/sec |

| 1.57 mm (Fine) |

5.5 nm |

1.75 mm/sec |

| 0.635 mm (Extra-fine) |

2.2 nm |

0.7 mm/sec |

* Standard Lead Screw Accuracy is 0.25 µm per millimeter

Linear Encoder Options

| Axis |

Scale Resolution |

Scale Accuracy |

| XY † |

10 nm |

± 3 µm per length of scale |

| Z (12 mm and 25 mm stroke) |

50 nm |

0.03 µm per mm |

† With XY linear encoders, only one stage wing may be attached

|

|

![]()